Migali Freezer Troubleshooting Guide

Your Migali freezer suddenly stops maintaining proper temperatures, and you’re staring at a growing puddle of melted ice as food begins to spoil. This frustrating scenario hits many commercial kitchen operators and homeowners who rely on Migali’s reputation for durability. When your C-3F or similar model fails to freeze properly—especially after a power outage—you face immediate food safety concerns and potential financial losses. Understanding how to quickly diagnose and address these issues can mean the difference between salvaging your inventory and facing hundreds in replacement costs. This guide delivers actionable troubleshooting steps specifically for Migali freezer models so you can identify problems with precision and determine whether you need professional assistance.

Temperature inconsistency represents the most frequent complaint among Migali freezer owners. Instead of maintaining the critical sub-zero environment required for food preservation, units may display readings between 35°F and 60°F—well above freezing temperatures. These fluctuations often emerge following power disruptions, though they can develop spontaneously in units with component wear. The underlying causes range from simple user errors to serious mechanical failures requiring technician intervention. By systematically checking the most common failure points in your specific model, you can often restore proper function without an immediate service call—or at least gather valuable diagnostic information to share with a repair professional.

Why Your Migali Freezer Won’t Freeze After Power Outage

Power outages create sudden stress on freezer components that can trigger cascading failures in your Migali unit. When electricity returns, the compressor may struggle to restart properly, or electronic controls can become confused about operating parameters. Migali C-3F freezers are particularly vulnerable to temperature inconsistencies following outages because the sudden power interruption disrupts the delicate balance between the compressor, thermostat, and sensors that maintain consistent cooling.

Perform an Effective Power Cycle Reset

When your Migali freezer fails to freeze after an outage, start by completely unplugging the unit and waiting ten full minutes before reconnecting power. This soft reset allows electronic controls to fully reinitialize and may resolve temporary malfunctions. During this waiting period, inspect the power cord for damage and verify the outlet functions by testing with another device. If the freezer powers on but still fails to cool properly after the reset, the problem likely involves a component failure rather than a simple control glitch. Document exact temperature readings at regular intervals—this information proves invaluable when consulting with repair technicians.

Decode Temperature Fluctuation Problems in Your Migali Unit

Erratic temperatures in Migali freezers typically stem from three root causes: airflow obstructions, sensor failures, or compressor performance issues. When temperatures vary between 35°F and 60°F depending on door opening frequency, your unit is struggling to recover cooling capacity after warm air enters. Each door opening introduces ambient air that the compressor must work harder to remove, but if the cooling system isn’t functioning properly, temperatures never stabilize.

Monitor Temperature Patterns for Accurate Diagnosis

Track the temperature for 24 hours while minimizing door openings to identify patterns. If the freezer gradually warms even with minimal access, the compressor or refrigerant system likely requires attention. Stable temperatures that only rise when the door opens suggest adequate cooling capacity with an airflow or seal problem. Many Migali models feature indicator lights or digital displays that provide diagnostic clues—consult your owner’s manual for model-specific error codes. Recording temperature readings at regular intervals creates a diagnostic pattern that points toward the specific component needing repair.

Check Door Seal and Airflow Issues Immediately

A compromised door seal allows warm air to infiltrate your Migali freezer continuously, forcing the compressor to run constantly while still failing to maintain low temperatures. Inspect the door gasket carefully for cracks, tears, or deformation along the sealing surface. Clean the gasket with mild soap and water to remove food residue or ice buildup that might prevent a tight seal. Test the seal by closing the door on a piece of paper—if you can pull the paper out easily without resistance, the gasket needs adjustment or replacement.

Optimize Internal Airflow for Consistent Cooling

Blocked airflow inside the freezer also causes temperature problems. Ensure stored items aren’t stacked directly against the back wall or blocking vents. Migali freezers rely on consistent air circulation around the evaporator coils to distribute cold air effectively. Over-packing the unit or arranging items in ways that create air pockets prevents proper cooling throughout the compartment. Leave at least two inches of space between stored items and the freezer walls, and avoid placing new items in front of existing stock until the unit has stabilized at the proper temperature.

Reset Your Migali Freezer Properly to Resolve Control Glitches

A proper reset can resolve control board glitches and restore normal operation in many Migali freezer problems. To perform a hard reset, unplug the unit from the wall outlet and leave it disconnected for a minimum of ten minutes. This duration allows capacitors to fully discharge and the electronic control board to reset completely. While unplugged, take the opportunity to inspect the power cord for damage and check that the outlet supplies consistent power to other devices.

Allow Proper Recovery Time After Reset

After reconnecting power, set the temperature control to the factory recommended setting—typically the middle position for most Migali models—and allow the freezer to run undisturbed for four to six hours before adding any food. During this initial recovery period, avoid opening the door unnecessarily so the compressor can establish proper cycling. If the freezer still fails to reach freezing temperatures after this reset period, the issue extends beyond a simple control malfunction and requires component-level troubleshooting or professional service.

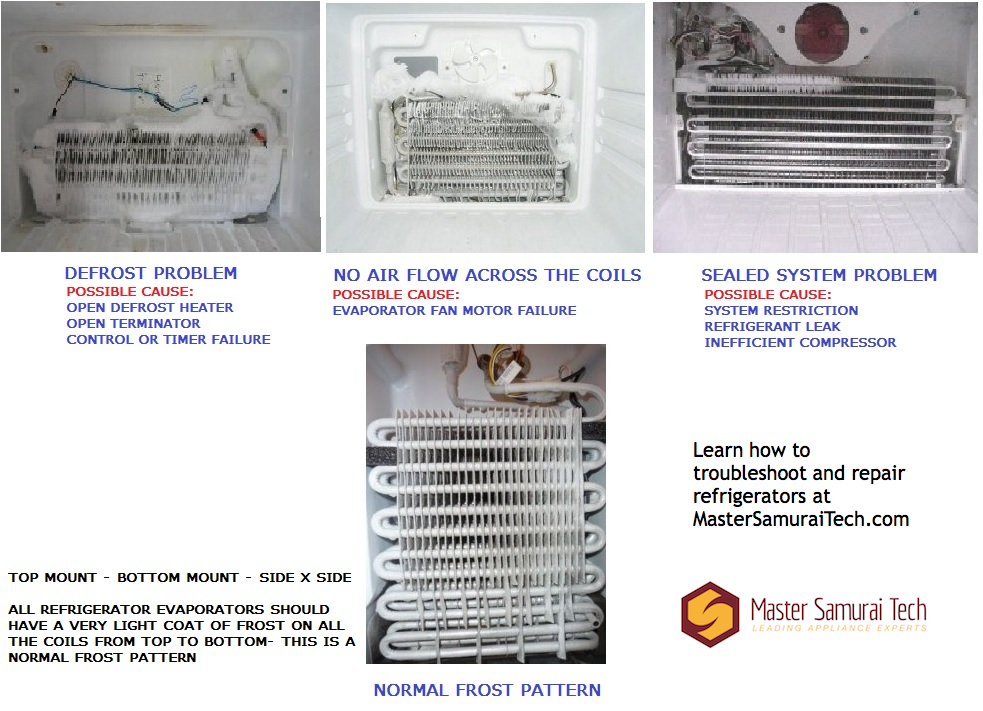

Inspect Evaporator Coils for Frost Buildup

Frost accumulation on evaporator coils blocks proper heat exchange and dramatically reduces cooling efficiency. When coils become heavily frosted, the freezer struggles to remove heat from the interior compartment, resulting in elevated temperatures and increased compressor runtime. This frost buildup often develops after door seal failures but can also indicate defrost system malfunctions in models equipped with automatic defrost cycles.

Identify and Address Frost-Related Cooling Issues

Visually inspect the evaporator coils through the freezer’s back panel or access cover. Light frost equal to a thin coating of ice is normal, but thick frost layers exceeding a quarter-inch indicate a problem. If you find excessive frost, turn off the freezer and allow the coils to thaw completely—this may take several hours depending on the frost thickness. Once thawed, dry the interior thoroughly before restarting. If frost returns within days, the defrost system (including the defrost heater, thermostat, or timer) likely requires replacement, which typically necessitates professional service.

When Compressor Issues Cause Cooling Failures

The compressor is the heart of your Migali freezer’s cooling system, and compressor failures result in complete or partial cooling loss. A running compressor that fails to produce cold air suggests internal mechanical problems, such as worn piston rings or valve failures that prevent proper refrigerant compression. Conversely, a compressor that won’t start at all may have failed electrically or may be locked up due to mechanical binding.

Recognize Warning Signs of Compressor Failure

Listen carefully to the compressor area when the freezer runs. A healthy compressor produces a steady, low hum, while clicking sounds followed by silence indicate repeated starting failures. Place your hand on the compressor housing during operation—excessive heat (too hot to touch comfortably for more than a few seconds) suggests the compressor is working too hard due to cooling system restrictions. Failed compressors typically require professional replacement because the repair involves handling refrigerant and electrical components that pose safety risks.

Replace Faulty Start Relay or Thermostat Components

The start relay helps your Migali freezer’s compressor begin running and is a common failure point in units experiencing startup problems. A faulty relay may prevent the compressor from starting entirely or cause intermittent operation that results in temperature fluctuations. The relay is usually located on the side of the compressor and can be tested with a multimeter or replaced relatively easily by homeowners comfortable with basic repairs.

Test and Replace Critical Control Components

The thermostat monitors interior temperatures and signals the compressor to cycle on and off. A stuck thermostat may fail to signal for cooling even when temperatures rise, or it may keep the compressor running continuously without shutting off at the proper temperature. Thermostat testing requires a multimeter to check for continuity at various temperature settings. Both components are relatively inexpensive and can be replaced without full compressor service. If you’re uncertain about testing procedures, replacing both the start relay and thermostat simultaneously often resolves startup and cycling issues at minimal cost.

Maintain Condenser Coils for Optimal Performance

Dirty condenser coils force the compressor to work harder and reduce overall cooling efficiency, eventually leading to temperature problems and premature component failure. Located either on the back or bottom of the unit, condenser coils dissipate heat removed from the freezer interior. When coated with dust, pet hair, or debris, heat transfer suffers and the cooling system becomes less effective.

Establish a Regular Coil Cleaning Routine

Clean condenser coils at least twice annually using a coil cleaning brush or vacuum with a brush attachment. For freezers with exposed coils, gently brush away debris in the direction of the fins to avoid damage. Coils located behind an access panel require removing the panel before cleaning. In addition to coil cleaning, keep the area around the freezer clear of dust and maintain adequate ventilation space according to the manufacturer’s specifications. Regular coil maintenance extends compressor life and helps maintain consistent operating temperatures.

Address Related Migali Cooling Problems Quickly

Beyond standard temperature issues, Migali refrigerators and freezers experience several related cooling problems requiring specific troubleshooting approaches. Condenser fan failures prevent proper heat dissipation and can cause both cooling loss and compressor overheating. If your Migali model C-1F shows the condenser fan not running after a motor replacement, the control circuit or new motor may have an electrical issue requiring further diagnosis.

Hot food loading stresses cooling systems and can temporarily elevate temperatures throughout the refrigerator and freezer compartments. Allow hot items to cool to room temperature before storing them, and avoid loading large quantities of warm food simultaneously. For Migali C-1RB-HC models experiencing cooling loss after hot food introduction, the compressor may need extended runtime to recover, but persistent problems suggest underlying issues exacerbated by the thermal stress. When freezer temperatures rise unexpectedly—readings climbing from the set -3°F to 15°F or higher—check door seals first, then inspect for frost buildup on evaporator coils. These symptoms indicate airflow or sealing problems rather than compressor failures in most cases.