How to Change Sub Zero Freezer Light Bulb

Changing a light bulb in your Sub-Zero freezer might seem like a simple task, but without proper manufacturer instructions, attempting this repair could lead to electrical hazards, warranty issues, or appliance damage. Unfortunately, specific guidance for Sub-Zero freezer light bulb replacement cannot be provided based on available official documentation. Sub-Zero appliances contain specialized components and safety mechanisms that require model-specific procedures. Before you attempt any maintenance on your high-end freezer, understanding the risks and limitations of DIY repairs is critical to protecting both your appliance and your safety.

Sub-Zero freezers operate with complex electrical systems integrated into their premium cooling technology. Unlike standard household freezers, these appliances often feature sealed compartments, specialized lighting fixtures, and electrical components that interact with the main control system. Without access to official Sub-Zero service manuals, attempting bulb replacement could inadvertently trigger error codes, compromise the appliance’s vacuum seal, or create electrical safety hazards. The average homeowner lacks the specialized tools and technical knowledge required for safe Sub-Zero maintenance, making professional service the only recommended approach for lighting issues.

Why Sub-Zero Repairs Require Specialized Knowledge

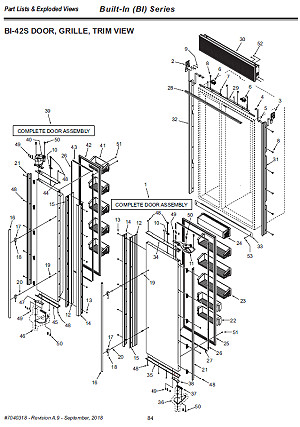

Unique Design Features That Complicate DIY Repairs

Sub-Zero freezers incorporate engineering elements that differ significantly from conventional appliances. The lighting system often integrates with the appliance’s control board, meaning a simple bulb replacement might require system recalibration. Many Sub-Zero models feature sealed lighting compartments designed to maintain optimal internal temperatures, which homeowners cannot properly reseal after accessing. The electrical components operate within strict specifications that require specialized testing equipment to verify safety after any service work. Attempting repairs without factory-authorized training risks creating conditions that could lead to electrical shorts or compromised cooling performance.

Warranty Implications of Unauthorized Service

Performing maintenance on your Sub-Zero freezer without authorized training immediately voids your warranty coverage. Sub-Zero’s warranty explicitly requires all service work to be performed by factory-certified technicians using genuine parts. Even seemingly minor interventions like bulb replacement can trigger internal diagnostics that register unauthorized access. The cost of voiding your warranty—potentially tens of thousands of dollars for major component failures—far exceeds the expense of professional service for a light bulb issue. Sub-Zero’s sophisticated monitoring systems detect when non-factory personnel have accessed internal components, making warranty restoration impossible after DIY attempts.

Essential Safety Precautions Before Considering Any Service

Power Disconnection Protocol

Before even considering accessing any internal components of your Sub-Zero freezer, you must completely disconnect power at the circuit breaker—not just unplug the unit. Sub-Zero appliances maintain power to critical components even when seemingly turned off, creating potential electrical hazards during service attempts. Allow the appliance to sit without power for at least 30 minutes before attempting any service to ensure capacitors have discharged. Never work on electrical components while the appliance is connected to power, as Sub-Zero’s commercial-grade electrical systems operate at potentially lethal voltages.

Frost and Condensation Management

Sub-Zero freezers maintain extremely low temperatures that create hazardous conditions when accessing internal components. Frost buildup around lighting fixtures can conceal electrical connections and create slip hazards during service attempts. Never use sharp objects to remove frost, as this can damage wiring insulation or puncture refrigerant lines. Allow the appliance to defrost completely before attempting any service work, which typically requires 24-48 hours with the door open and proper drainage management. Working in a partially defrosted Sub-Zero creates dangerous conditions where condensation can contact electrical components.

Why Professional Service Is the Only Recommended Option

Factory-Authorized Technician Advantages

Sub-Zero factory-certified technicians carry specialized tools unavailable to consumers, including diagnostic equipment that interfaces with the appliance’s control system. They receive ongoing training on model-specific service procedures and understand the complex interrelationships between components in these premium appliances. Authorized technicians use genuine Sub-Zero parts engineered to precise specifications, ensuring proper fit and function within the appliance’s integrated systems. Most importantly, they follow strict service protocols that maintain your warranty coverage and prevent the cascade of problems that often follow well-intentioned DIY repairs on high-end appliances.

Cost-Benefit Analysis of Professional Service

While the cost of professional service might seem high compared to a simple bulb replacement on a standard appliance, it represents excellent value when considering the total cost of ownership. A typical Sub-Zero service call for lighting issues ranges from $150-$300, while a single DIY mistake could trigger $1,000+ in repair costs or complete warranty voidance. Factory technicians can identify and address underlying issues that might have caused the bulb failure, preventing future problems. The time investment required to properly service a Sub-Zero correctly far exceeds what homeowners can reasonably accomplish without specialized knowledge and tools.

What to Do When Your Sub-Zero Freezer Light Fails

Immediate Diagnostic Steps

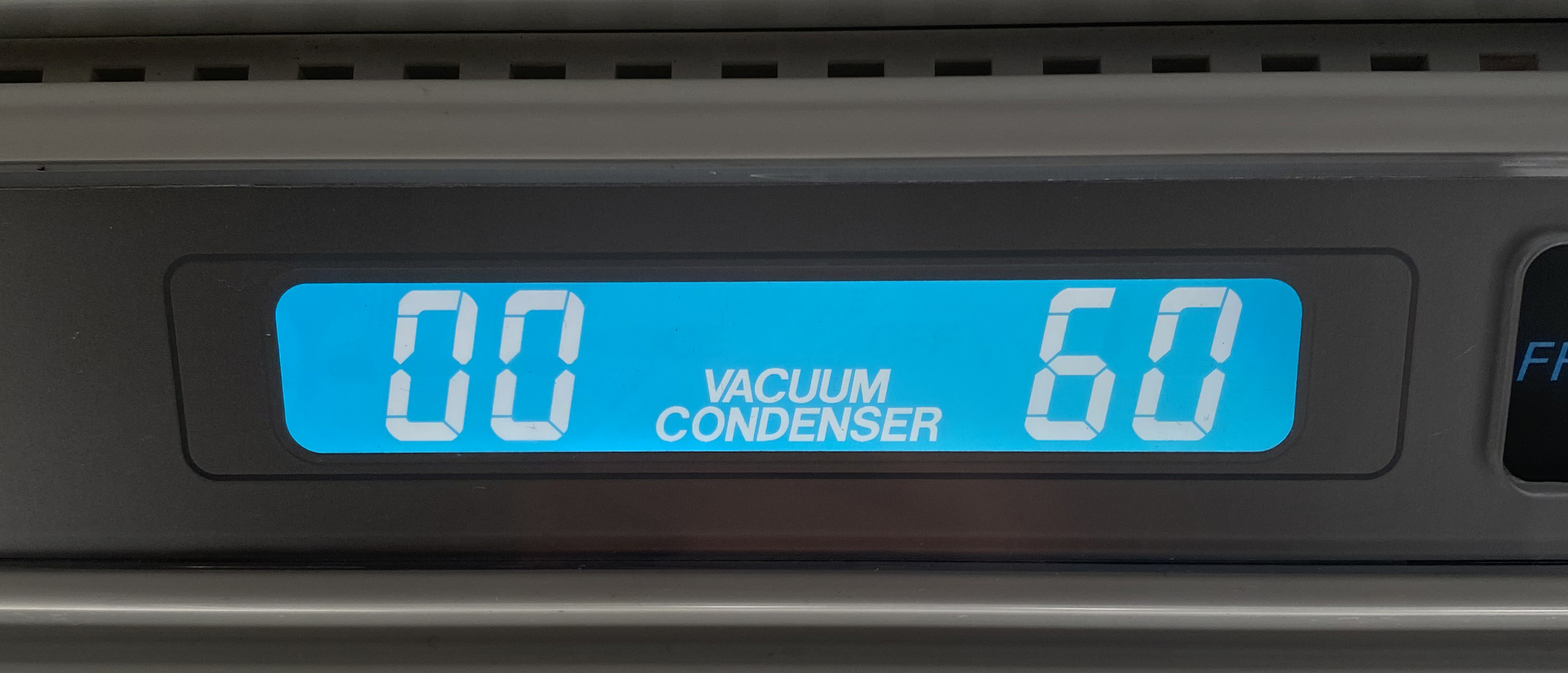

When your Sub-Zero freezer light stops working, first verify whether the issue affects only the lighting or indicates a broader electrical problem. Check if other electrical components function normally, including the control panel, fan operation, and temperature maintenance. Note any error codes displayed on the control panel that might indicate system-wide electrical issues. Avoid repeatedly opening and closing the door to test the light, as this stresses the compressor and increases energy consumption. Document all symptoms precisely to provide accurate information to Sub-Zero service personnel.

Contacting Sub-Zero Customer Support

Sub-Zero provides dedicated customer support channels specifically designed to address service needs for their premium appliances. Contact Sub-Zero directly through their official service hotline rather than relying on third-party repair services. Provide your complete model and serial number when requesting service, as procedures vary significantly between Sub-Zero product lines. Ask specifically for a factory-authorized technician with current certification for your exact model. Sub-Zero’s customer service team can often provide preliminary troubleshooting over the phone to determine whether the issue requires immediate attention or can wait for scheduled service.

Preventive Measures to Minimize Future Lighting Issues

Understanding Bulb Lifespan Factors

Sub-Zero freezer bulbs operate in extreme conditions that significantly reduce their expected lifespan compared to standard household bulbs. Frequent door openings expose bulbs to rapid temperature fluctuations that cause premature filament failure. Moisture infiltration during normal operation creates conditions that accelerate corrosion of electrical contacts. Using non-Sub-Zero specified bulbs creates compatibility issues that lead to early failure and potential safety hazards. Understanding these factors helps set realistic expectations about lighting maintenance requirements for premium appliances.

Proper Usage Habits to Extend Bulb Life

Minimize door openings to reduce thermal stress on lighting components and extend bulb lifespan. Ensure the door seals properly after each closure to prevent excessive frost buildup around the lighting compartment. Never install higher-wattage bulbs than specified, as this creates dangerous heat conditions within the sealed compartment. Clean door gaskets regularly to maintain proper sealing, which reduces moisture infiltration that damages lighting components. These simple habits significantly reduce the frequency of lighting issues in your Sub-Zero freezer.

Final Considerations for Sub-Zero Owners

When facing any maintenance issue with your Sub-Zero appliance, remember that these are precision-engineered systems where components interact in complex ways. What appears to be a simple bulb replacement might involve multiple integrated systems requiring specialized knowledge. The investment in professional service protects your substantial appliance investment and ensures continued optimal performance. Sub-Zero’s exceptional build quality means that with proper professional maintenance, your appliance will deliver reliable service for decades. Always prioritize safety and warranty protection over the temporary convenience of DIY repairs on these sophisticated, high-value appliances.

For definitive guidance on your specific Sub-Zero model, contact Sub-Zero directly through their official customer service channels to obtain accurate, model-specific instructions from factory-authorized personnel. Your appliance’s longevity and performance depend on following proper service protocols designed specifically for these premium systems.