How Does a Freezer Work: Simple Explanation

Ever wonder how your freezer keeps food frozen for months while using relatively little energy? Understanding how does the freezer work reveals a brilliant application of thermodynamics that has transformed food preservation. At its core, your freezer operates through a continuous refrigeration cycle that systematically removes heat from the interior and expels it to the surrounding environment. This process maintains temperatures at or below 0°F (-18°C), effectively pausing the biochemical processes that cause food to spoil. By the time you finish this guide, you’ll know exactly how each component contributes to keeping your food safely frozen.

Whether you have a compact freezer drawer in your refrigerator or a standalone chest freezer in your garage, all these appliances share the same fundamental technology. The refrigeration cycle has remained remarkably consistent since its development, though modern refinements have improved energy efficiency and temperature consistency. Knowing how your freezer operates helps you optimize its performance, troubleshoot issues, and extend its service life—saving you money and preventing food waste in the process.

Core Components Powering Your Freezer’s Cooling System

Your freezer relies on four critical components working in perfect harmony to create and maintain freezing temperatures. These parts form a closed-loop system where refrigerant continuously circulates, changing states to absorb and release heat. Understanding each element’s role makes the entire process much clearer and helps you identify potential problems when they arise.

The Compressor: Your Freezer’s Powerhouse

The compressor acts as your freezer’s beating heart, usually positioned at the bottom rear where it can efficiently dissipate heat. This motor-driven pump draws in low-pressure refrigerant vapor and compresses it into a high-pressure, high-temperature gas—significantly increasing its thermal energy in the process. When you hear your freezer cycle on, that distinctive hum comes from the compressor activating to begin the cooling process.

Your freezer’s thermostat constantly monitors internal temperature, triggering the compressor whenever temperatures rise above your set point. Once the interior cools sufficiently, the compressor shuts off, conserving energy until cooling is needed again. This cycling on and off is completely normal operation, not a sign of malfunction—your freezer only runs when necessary to maintain optimal freezing conditions.

Condenser Coils: Heat Release System

The condenser coils function as your freezer’s primary heat exchanger, typically located underneath or along the back exterior where room-temperature air can flow across them. As the hot, pressurized refrigerant from the compressor enters these coils, it begins releasing thermal energy to the surrounding environment. This heat transfer causes the refrigerant to undergo a critical phase change from vapor to liquid.

You’ve probably noticed your freezer feels warm to the touch during operation—that’s the condenser doing its job effectively. As refrigerant flows through these coils, it gradually cools while maintaining high pressure, emerging as a warm liquid ready for the next stage. If these coils become covered in dust or debris, your freezer must work harder to dissipate heat, significantly reducing efficiency and increasing energy consumption.

Expansion Valve: Creating the Critical Temperature Drop

The expansion valve (or capillary tube in smaller units) creates the dramatic pressure reduction that enables effective cooling inside your freezer. Positioned between the condenser and evaporator, this narrow passage forces high-pressure liquid refrigerant to expand rapidly as it passes through. This sudden pressure drop causes the refrigerant temperature to plummet dramatically—some of it even “flashes” into a two-phase mixture of liquid and gas.

This temperature reduction is absolutely essential because it prepares the refrigerant to absorb heat efficiently from your freezer’s interior. Without this critical pressure drop, the refrigerant couldn’t reach the low temperatures needed to freeze your food. The expansion valve essentially transforms warm liquid refrigerant into a super-cooled mixture ready to absorb thermal energy from everything inside your freezer.

Evaporator: Interior Cooling Mechanism

Hidden behind your freezer’s interior walls, the evaporator absorbs heat from the air and food inside your appliance. As the cold, low-pressure refrigerant mixture enters these coils, it begins soaking up thermal energy from the surrounding environment. This heat absorption causes the refrigerant to evaporate completely, transforming back into a low-pressure gas that returns to the compressor to restart the cycle.

Most freezers include internal fans that circulate air across the evaporator’s fins, ensuring consistent cold temperatures throughout the entire compartment. When you see frost building up on the evaporator coils, that’s moisture from the air freezing onto these extremely cold surfaces—a normal occurrence that automatic defrost systems address in modern freezers.

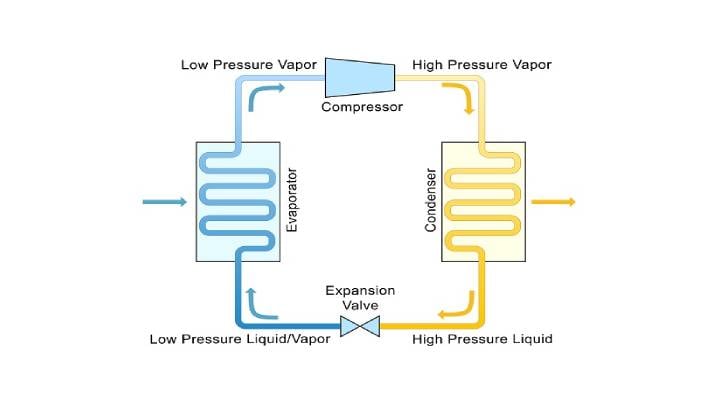

The Complete Refrigeration Cycle in Action

Your freezer operates through a continuous loop where refrigerant circulates through these four components, systematically absorbing and releasing heat to maintain freezing temperatures. This cycle runs constantly, with refrigerant transforming between liquid and gas states as it travels through the system. Understanding each phase reveals the elegant simplicity behind this essential technology.

Step 1: Compression Creates High-Pressure Refrigerant

The cycle begins when the compressor draws in low-pressure refrigerant vapor and squeezes it into a high-pressure, high-temperature gas. This mechanical compression heats the refrigerant significantly—sometimes to temperatures exceeding 200°F—creating the necessary conditions for effective heat transfer in the next stage. The compressor pumps this hot, pressurized gas through tubing to the condenser coils, where it begins releasing its thermal energy.

Step 2: Condensation Releases Heat to the Environment

As the hot refrigerant enters the condenser coils, it gradually releases heat to the surrounding air while maintaining high pressure. This heat transfer causes the refrigerant to undergo its crucial phase change from vapor to liquid. The condenser transforms the high-pressure gas into a warm-temperature liquid that still carries significant pressure to push it through the rest of the system. This is why the exterior of your freezer often feels warm during operation—it’s actively expelling heat from inside the appliance.

Step 3: Expansion Causes Dramatic Cooling

The liquid refrigerant then flows into the expansion valve or capillary tube, where it encounters a sudden pressure drop. This rapid expansion causes the refrigerant temperature to plummet dramatically—sometimes below -20°F—creating the extremely cold conditions needed for effective freezing. Some of the refrigerant flashes into vapor during this process, creating the two-phase mixture that maximizes heat absorption in the evaporator.

Step 4: Evaporation Absorbs Interior Heat

The super-cooled refrigerant mixture now enters the evaporator coils inside your freezer compartment. As it flows through these coils, it absorbs heat from the air and food inside, causing the refrigerant to evaporate completely. This heat absorption lowers the interior temperature, creating the freezing conditions that preserve your food. The now-warmed vapor returns to the compressor to begin the cycle again, maintaining consistent freezing temperatures throughout your appliance.

Temperature Control Systems in Your Freezer

Your freezer maintains precise temperatures through the interplay between mechanical refrigeration, thermal insulation, and electronic controls. The thermostat constantly monitors internal temperature, activating the compressor whenever temperatures rise above your set point. Most freezers operate optimally at 0°F (-18°C), the temperature that best preserves food while balancing energy efficiency.

If your ice cream is rock-hard and difficult to scoop, your freezer may be set too cold. Conversely, frequent frost buildup on walls often indicates temperatures are too high. In refrigerator-freezer combinations, the freezer typically has its own dedicated cooling circuit, allowing it to reach 0°F while the refrigerator section maintains around 40°F through carefully controlled airflow.

Optimizing Freezer Performance and Longevity

Regular maintenance dramatically extends your freezer’s service life while improving efficiency. Vacuum condenser coils every 6-12 months to remove dust buildup that insulates these critical heat exchangers. Check door seals monthly by closing them on a dollar bill—if you can pull it out easily, replace the gasket to prevent cold air leakage.

Never overload your freezer to the point where items block airflow vents or the evaporator fan. Proper air circulation ensures consistent temperatures throughout the compartment. When adding warm food, cool it to room temperature first to prevent temperature spikes that force your compressor to work overtime. Following these simple practices keeps your freezer operating at peak efficiency while preserving your food quality.

Troubleshooting Common Freezer Issues

When your freezer fails to maintain proper temperatures, start with these simple checks before calling for service:

- Verify thermostat settings—your freezer should be set at or below 0°F

- Check for airflow obstructions—rearrange contents to ensure vents remain clear

- Clean condenser coils—dust buildup significantly reduces cooling efficiency

- Inspect door seals—replace cracked or worn gaskets that allow cold air leakage

If frost buildup exceeds ¼ inch thickness, perform a manual defrost—excessive ice insulates interior surfaces and reduces cooling efficiency. For frost-free models experiencing rapid frost accumulation, the defrost heater or timer may require professional attention.

Maximizing Energy Efficiency

Modern freezers incorporate numerous energy-saving features, but your usage habits significantly impact operating costs. Place your freezer away from heat sources like ovens or direct sunlight, which force it to work harder. Ensure at least 2-3 inches of clearance around the unit for proper ventilation, especially at the rear where condenser coils release heat.

Garage installations require special consideration—only use models specifically rated for garage temperatures, as standard freezers may struggle in environments below 50°F or above 110°F. ENERGY STAR certified models typically use 10-20% less energy than non-certified units while delivering equivalent performance.

Preventing Freezer Burn and Maintaining Food Quality

Freezer burn occurs when dry air dehydrates food surfaces, creating dry, leathery patches that affect texture and flavor. Prevent it by:

- Cooling foods completely before freezing

- Using airtight, moisture-proof packaging

- Removing as much air as possible from containers

- Vacuum sealing for maximum protection

Properly packaged foods maintain quality for 8-12 months at 0°F. While frozen food remains safe indefinitely, quality gradually declines over time. Label all items with dates and use a first-in, first-out system to ensure optimal freshness.

Understanding how does the freezer work empowers you to use this essential appliance more effectively while extending its service life. By maintaining proper temperatures, ensuring adequate airflow, and performing regular maintenance, you’ll keep your freezer operating efficiently for years to come—preserving food quality while minimizing energy costs and preventing common problems.