Ultra Low Temperature Freezer Repair Guide

Ultra-low temperature freezer repair is critical for laboratories relying on -50°C to -86°C storage systems. These specialized cascade refrigeration units preserve biological samples, vaccine stockpiles, and research materials representing years of scientific investment. When ULT freezer failures occur, the consequences can be devastating—irreplaceable samples lost, research delayed, and compliance jeopardized. Proactive repair strategies and reliable service partnerships are essential for any facility managing temperature-sensitive materials.

A single temperature excursion above -70°C can permanently degrade cell lines, proteins, and nucleic acids stored for years. For biobanks maintaining rare disease specimens or clinical trial materials, freezer failures represent catastrophic risks that can set back scientific progress by years. This guide provides actionable insights for preventing failures, selecting appropriate repair services, and implementing maintenance protocols that protect your valuable collections from preventable loss.

Why Your -80°C Freezer Repair Requires Specialized Technical Expertise

Unlike standard commercial freezers, ultra-low temperature units employ complex cascade refrigeration systems that demand specialized diagnostic and repair skills. General appliance technicians typically lack the training to effectively address ULT-specific failure modes, risking improper repairs that compromise sample integrity.

The Hidden Complexity of Cascade Refrigeration Systems

ULT freezers use multiple refrigeration stages working in series to achieve extreme temperatures, creating unique failure points that general technicians often misdiagnose. When compressors fail in one stage, the entire system collapses—yet symptoms may initially appear as simple temperature fluctuations. Only technicians with factory training on specific models can accurately trace these interconnected failures through the cascade system.

Expert Tip: If your freezer shows inconsistent temperatures but no error codes, request a technician specifically trained on your model. Generic “one-size-fits-all” approaches often miss cascade-specific issues that develop gradually before complete failure.

Consequences of Inadequate ULT Freezer Repair

Improper repairs lead to recurring failures that gradually degrade system performance while creating dangerous false security. A study of laboratory freezer incidents revealed that facilities using non-specialized repair services experienced 37% more repeat failures within six months compared to those using OEM-trained technicians. Each repeat failure increases the risk of undetected temperature excursions that compromise sample viability without triggering alarms.

ULT Freezer Service Plans Compared: Response Times, Coverage, and Costs

Choosing the right service coverage requires balancing budget constraints against the catastrophic cost of sample loss. Major service providers offer tiered plans with significant differences in response capabilities and coverage scope that directly impact your risk exposure.

Tech Direct vs. Total Care: Which ULT Repair Plan Fits Your Needs?

For facilities storing irreplaceable samples, the Total Care Service Plan’s two-business-day response commitment often justifies its higher cost. This plan provides 50% faster technician dispatch than the Tech Direct option, which targets three business days for on-site response. Consider this critical comparison:

- Total Care: Two-business-day response, 1-year repair warranty, discounted compliance services

- Tech Direct: Three-business-day response, 1-year repair warranty, no loaner equipment

- Break-Fix: Variable response (often 5+ days), 90-day repair warranty, full-price parts

Pro Tip: Calculate your sample replacement cost per hour of downtime. If it exceeds $500/hour (common for clinical trial materials), the premium service plan’s faster response likely pays for itself during your first emergency.

When Remote Support Resolves ULT Freezer Issues Without On-Site Visits

Modern ULT freezers with smart connectivity enable technicians to diagnose and resolve up to 50% of issues remotely. These remote resolutions typically occur within 4-6 hours versus the 24-72 hours required for on-site visits. Smart Connected Services monitor system parameters continuously, alerting technicians to developing issues before they trigger temperature excursions.

Top 5 ULT Freezer Failure Modes That Risk Sample Integrity

Recognizing early warning signs of common failures allows you to schedule repairs before catastrophic temperature excursions occur. These five failure patterns account for over 75% of ULT freezer service calls.

Compressor Failures: The Silent Sample Killer

Cascade compressor failures often begin with subtle symptoms: extended run times, reduced cooling capacity, or unusual vibration patterns. Many labs mistake these for normal operation until temperatures suddenly rise above -70°C. Visual cue: Check for oil accumulation beneath the unit—that’s your first warning sign of compressor distress.

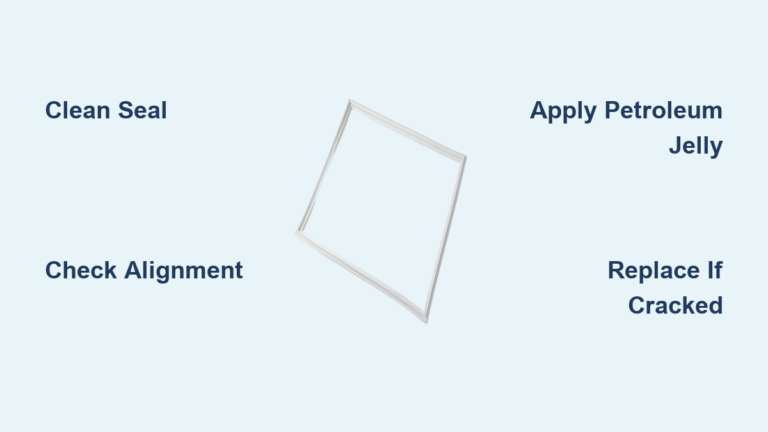

Door Seal Degradation: The Hidden Air Infiltration Problem

Brittle or cracked door gaskets allow warm, moist air to infiltrate your freezer, causing excessive frost buildup and temperature instability. Quick test: Close the door on a dollar bill—if you can pull it out easily at any point around the seal, replacement is needed immediately. Delaying this simple repair increases energy consumption by 15-20% while stressing the refrigeration system.

Prevent ULT Freezer Failures: Critical Maintenance and Validation Services

Proactive maintenance prevents 83% of catastrophic failures according to industry data. These validation services form the foundation of reliable ULT freezer operation.

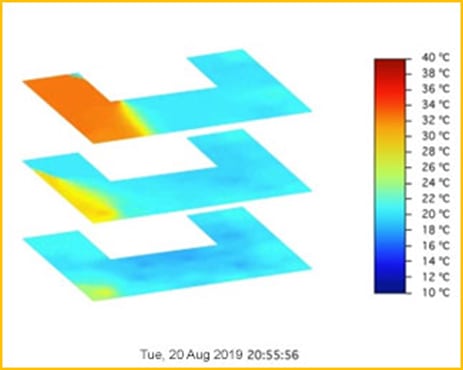

Temperature Mapping: Your Insurance Policy Against Sample Loss

Comprehensive temperature mapping identifies dangerous thermal gradients within your storage compartment. Standard protocols include:

- 24-hour steady-state monitoring at multiple locations

- Door opening recovery tests measuring rebound rates

- Backup system verification during simulated power failures

Expert Note: Mapping should be repeated annually or after any major repair. Thermal performance degrades over time as components wear, creating previously undetected cold spots or warm zones.

Calibration Services: Why “Close Enough” Isn’t Acceptable

Miscalibrated temperature probes create dangerous false security—your freezer may display -80°C while actual temperatures hover at -65°C. Annual calibration against traceable standards ensures your monitoring system provides accurate readings within ±0.5°C. Facilities operating under 21 CFR Part 11 requirements must document calibration dates, standards used, and technician credentials.

Passing FDA Inspections: ULT Freezer Compliance Repair Protocols

Regulatory agencies increasingly scrutinize freezer maintenance records during inspections. Proper documentation of repair and validation activities prevents citations that can halt research or production.

Installation and Operation Qualification: Beyond Basic Repair

After any major repair, complete Installation Qualification (IQ) and Operation Qualification (OQ) documentation to maintain audit readiness. These protocols verify that:

- Equipment positioning meets manufacturer specifications

- Utility connections function properly

- Control systems respond accurately to setpoint changes

- Alarm functionality operates as designed

Critical Mistake to Avoid: Skipping post-repair validation. A single unqualified repair event can invalidate your entire equipment validation history during an FDA inspection.

24/7 ULT Freezer Monitoring: Catch Problems Before Samples Are Lost

Remote monitoring transforms freezer management from reactive to proactive, providing continuous visibility regardless of staff presence.

Implementing Predictive Maintenance Through Data Analytics

Modern monitoring platforms analyze performance trends to predict failures before they occur. Watch for these early warning signs in your data:

- Gradual increases in compressor run time

- Slower door recovery rates

- Rising condenser temperatures

- Increased defrost cycle frequency

Pro Tip: Set custom alerts for “trending” parameters, not just absolute temperature thresholds. Catching developing issues early prevents 68% of catastrophic failures.

Finding Genuine ULT Freezer Parts: Avoid Costly Repair Mistakes

Using non-OEM parts voids warranties and creates compatibility issues that lead to repeat failures. Authorized service providers maintain extensive inventories of factory-certified components specific to your model.

Critical Components That Demand Genuine Replacement Parts

When repairing ULT freezers, never compromise on these components:

- Temperature sensors and probes (aftermarket versions often lack required accuracy)

- Compressor assemblies (cascade systems require precisely matched components)

- Control boards (firmware compatibility is critical)

- Door gaskets (material composition affects seal integrity at ultra-low temps)

Expert Warning: Aftermarket door gaskets frequently use inferior materials that become brittle at -80°C, failing within months rather than years.

Extend Your -80°C Freezer Life: 5 Strategic Repair and Maintenance Tactics

Maximize equipment longevity while protecting samples with these evidence-based strategies:

Schedule Preventive Maintenance Based on Usage, Not Just Time

Freezers in high-traffic labs (10+ daily door openings) need service twice as often as those in low-usage environments. Adjust your PM schedule according to:

- Daily door access frequency

- Ambient temperature and humidity conditions

- Sample loading patterns

- Historical performance data

Time-Saving Shortcut: Implement a digital maintenance log that automatically schedules service based on usage metrics rather than calendar dates.

ULT Freezer Repair Cost vs. Risk Analysis: Protecting Irreplaceable Samples

The true cost of inadequate repair extends far beyond service bills. Calculate your risk exposure with this simple formula:

(Sample replacement cost) × (Probability of failure) = Justifiable repair investment

For facilities storing irreplaceable clinical specimens or decade-long research collections, this calculation often justifies premium service coverage. Facilities with robust remote monitoring and preventive maintenance programs report 40% fewer catastrophic failures and 30% lower total repair costs over equipment lifecycles.

Final Recommendation: Treat ULT freezer repair as sample protection insurance rather than equipment maintenance expense. The investment in specialized service pays exponential dividends when it prevents a single temperature excursion that would destroy years of scientific work. Document all maintenance activities, validate performance after repairs, and implement remote monitoring—you’ll sleep better knowing your irreplaceable collections remain protected at -80°C.