How to Clean a Commercial Freezer Floor

A commercial freezer floor that’s slick with ice, covered in frost, or stained with food residue creates serious safety hazards and food contamination risks in your foodservice operation. When your walk-in freezer floor isn’t properly maintained, you’re facing potential slip-and-fall injuries, failed health inspections, and even costly floor damage that requires expensive repairs. The extreme conditions of commercial freezer environments—constant sub-zero temperatures, moisture from door openings, and heavy foot traffic—demand specialized cleaning approaches that standard kitchen floor protocols simply can’t address. This guide delivers the precise steps you need to maintain safe, sanitary, and compliant freezer floors, whether you’re managing a restaurant walk-in, grocery store cold storage, or industrial food processing facility.

Most operators underestimate how quickly freezer floors deteriorate without proper maintenance. Within weeks, a neglected freezer floor develops dangerous ice buildup, creates bacterial breeding grounds in cracks and crevices, and becomes increasingly difficult to clean effectively. By implementing the systematic approach outlined here, you’ll prevent these common problems while ensuring your freezer floor supports rather than hinders your daily operations. You’ll learn not just how to clean your freezer floor properly today, but how to establish maintenance routines that keep it in peak condition for years to come.

Gather Essential Cleaning Supplies Before Entering the Freezer

Assembling the right tools before stepping into the freezer prevents wasted time and ineffective cleaning that leads to recurring problems. Commercial freezer floor cleaning demands specialized equipment that functions properly in sub-zero temperatures—standard cleaning tools often fail or become dangerous when exposed to extreme cold.

Your essential supply kit must include a stiff-bristled push broom with nylon or polypropylene bristles specifically rated for cold environments, as regular brooms become brittle and break below freezing. Industrial floor squeegees with cold-rated rubber blades maintain flexibility to effectively remove wash water before it refreezes. Invest in a high-capacity mop and wringer system with synthetic fibers that won’t stiffen in cold conditions—microfiber mops excel at absorbing moisture without freezing solid. Use insulated five-gallon buckets with snap-on lids to prevent your cleaning solutions from freezing during application.

For cleaning solutions, select EPA-registered sanitizers formulated for food contact surfaces that remain effective at freezer temperatures—most standard quaternary ammonium disinfectants lose potency below 40°F. Consider adding absorbent floor dry compounds or non-clumping cat litter for moisture absorption before mopping, and keep ice melt products designed for walk-in coolers nearby to prevent refreezing on surrounding surfaces. Never attempt freezer floor cleaning with standard household cleaners—they won’t sanitize properly in cold conditions and may damage your flooring.

Prepare the Freezer Environment to Prevent Hazardous Ice Buildup

Effective preparation transforms a potentially dangerous cleaning task into a safe, efficient process that delivers lasting results. Commercial freezer floor cleaning requires strategic environmental management to prevent accidents and ensure thorough cleaning without creating new hazards.

Begin by removing all movable equipment, storage containers, and debris from the floor surface. If your freezer allows temperature adjustment, consider raising the temperature 5-10 degrees 30 minutes before cleaning to slow the refreezing process—just be careful not to compromise stored product safety. Open the freezer door and ensure any exhaust vents are clear to provide adequate ventilation, as cleaning chemicals concentrate quickly in enclosed cold spaces.

Thoroughly sweep the entire floor with your cold-rated broom, paying special attention to corners, under shelving units, and around door thresholds where frost accumulates most heavily. For significant ice buildup, use a plastic scraper (never metal, which can damage flooring) to remove large chunks before applying liquid solutions—this prevents spreading ice fragments across the floor during wet cleaning. Critical safety note: Always wear slip-resistant footwear rated for sub-zero temperatures during this preparation phase to prevent falls on icy surfaces.

Apply Deep Cleaning Solution Using Temperature-Appropriate Techniques

Applying your cleaning solution correctly determines whether your effort removes contaminants or merely redistributes them across the frozen surface. Commercial freezer floors require specialized application methods because standard cleaning techniques fail when solutions freeze before they can work.

Mix your cleaning solution using warm water (100-110°F) to counteract the ambient cold—this extends the working time before freezing occurs. For heavily soiled areas, consult your sanitizer’s technical data sheet for cold-temperature dilution rates, as standard concentrations often prove ineffective below freezing. Apply the solution systematically starting from the back of the freezer and working toward the door to avoid trapping yourself in a wet, freezing area.

Use a deck brush with stiff bristles to work the cleaning solution into the floor surface, focusing on heavily trafficked areas, spill zones, and textured sections near door thresholds. Allow the solution to remain on the surface for the full contact time specified on your sanitizer label—cold temperatures often require extended contact times (10-15 minutes) for proper sanitization. Pro tip: Work in small sections (4’x4′) to prevent the solution from freezing before you can complete the scrubbing process.

Remove Wash Water Thoroughly to Prevent Dangerous Ice Formation

The difference between a safely maintained freezer floor and a hazardous skating rink lies in proper water removal technique. Leaving even small amounts of moisture on a freezer floor creates immediate slip hazards and leads to permanent ice buildup that damages flooring over time.

Using your cold-rated squeegee, push all wash water toward the floor drain or lowest point of the floor in systematic, overlapping strokes. For areas without drains, apply absorbent compounds to soak up remaining moisture, then sweep and dispose of the saturated material immediately—never allow standing water to remain, even briefly. After squeegeeing, perform a second pass with a dry microfiber mop to eliminate the thin moisture film that inevitably remains in grout lines and textured surfaces.

Common mistake alert: Many operators skip this second drying pass, assuming the squeegee removed all moisture. This oversight creates invisible ice patches that cause slips and falls hours after cleaning. For high-traffic facilities, consider placing temporary warning signs at the entrance for 30 minutes after cleaning to alert staff to potentially slippery conditions.

Address Stubborn Stains with Targeted Cleaning Protocols

Despite regular maintenance, commercial freezer floors develop persistent stains from food products, packaging materials, or chemical residue that require specialized treatment. Ignoring these problem areas creates bacterial harborage zones that compromise food safety.

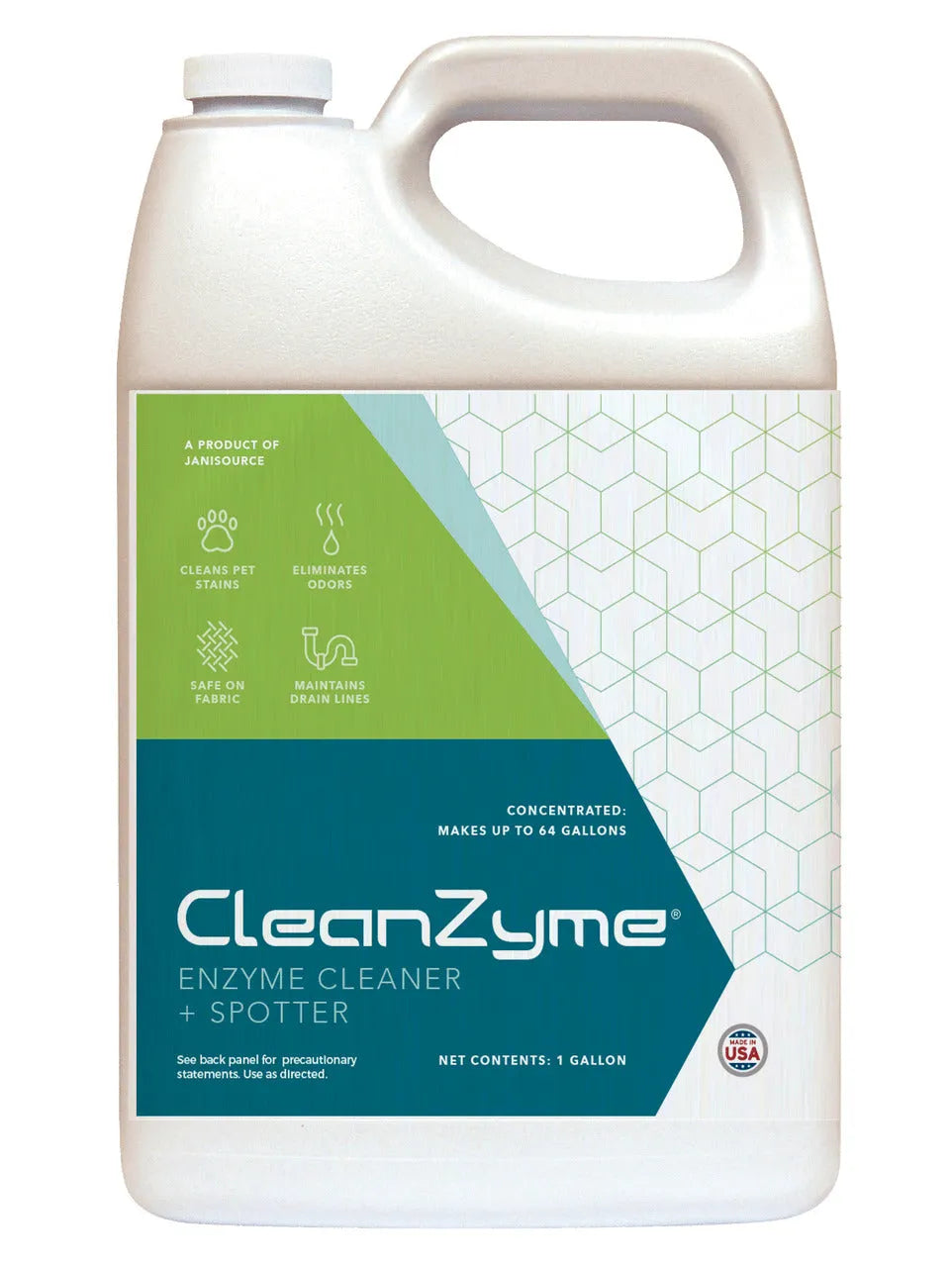

For protein-based stains (blood, meat juices, dairy), apply an enzymatic cleaner designed for food processing environments and allow it to work for the full recommended contact time before scrubbing. These cleaners break down organic matter at a molecular level and work effectively where standard alkaline cleaners fail in cold temperatures. Grease and oil stains respond best to degreasing agents formulated for low-temperature use—apply directly to the stained area, allow penetration according to label directions, then scrub with a stiff brush.

Expert note: For particularly stubborn buildup, create a paste of baking soda and cold water, apply it to the stain the night before your scheduled cleaning, and cover with plastic wrap—the extended dwell time loosens residue for easier removal during your regular cleaning routine.

Sanitize for Food Safety Compliance with Cold-Temperature Approved Solutions

Sanitizing your commercial freezer floor isn’t optional—it’s a regulatory requirement under FDA Food Code that prevents cross-contamination and maintains food safety certification. Proper floor sanitization requires products specifically formulated to work in sub-zero environments.

Select sanitizers verified for effectiveness at freezer temperatures—hydrogen peroxide-based solutions or steam cleaning systems often outperform traditional quaternary ammonium compounds in extreme cold. Apply sanitizer at the proper concentration using a clean mop or spray bottle, ensuring complete coverage of the entire floor surface. Allow the sanitizer to remain wet for the full contact time specified on the label (typically 10-15 minutes in cold conditions), then let it air dry—never rinse after sanitizing, as this removes the protective antimicrobial film.

Critical compliance tip: Document the specific sanitizer used, concentration, contact time, and temperature conditions during each cleaning session—health inspectors frequently request this information during routine visits.

Establish a Customized Cleaning Schedule Based on Your Facility’s Needs

Consistent maintenance prevents the severe buildup that makes cleaning difficult and time-consuming. A structured cleaning schedule tailored to your facility’s usage patterns keeps floors compliant with minimal daily effort.

Daily cleaning should focus on quick spill response and surface-level sweeping—spend 10-15 minutes at the end of each service day spot-cleaning visible spills and sweeping high-traffic areas. Weekly deep cleaning involves the complete process outlined above, with high-volume operations requiring twice-weekly sessions. Monthly maintenance should include thorough inspection of floor surfaces, grout lines, and expansion joints, with deep treatment of any problem areas identified.

Time-saving shortcut: Create a cleaning checklist specific to your freezer’s size and traffic patterns—this ensures no steps are missed during routine maintenance and provides documentation for health inspections.

Prevent Future Floor Damage with Proactive Protective Measures

Implementing simple protective strategies extends your commercial freezer floor’s lifespan and reduces intensive cleaning frequency. Understanding the factors that damage freezer floors helps you implement cost-effective preventive measures.

Place walk-off mats designed for cold environments at freezer entrances to reduce moisture and debris tracked onto the floor surface. Install protective floor mats in high-traffic zones and beneath frequently opened doors to shield the underlying floor from excessive wear. Address standing water or drainage issues immediately, as prolonged moisture exposure degrades floor sealants and promotes ice formation.

Expert recommendation: Inspect door seals and gaskets monthly—damaged seals allow humid air infiltration that accelerates frost buildup on floors and throughout the freezer interior, creating ongoing maintenance challenges.

Maintain Documentation to Demonstrate Compliance During Health Inspections

Detailed cleaning records protect your facility during health inspections and help identify maintenance patterns before minor issues become major problems. Comprehensive documentation shows regulators your commitment to food safety standards.

Keep a cleaning log in or near the freezer that records each cleaning activity including date, time, cleaner used, technician name, and observations about floor condition. Schedule quarterly floor inspections as part of your preventive maintenance program, documenting any cracks, sealant degradation, or drainage issues requiring professional attention.

Critical compliance strategy: Train all staff on proper freezer floor maintenance protocols and documentation requirements—consistent execution across your team ensures compliance even when key personnel are unavailable.

A clean commercial freezer floor is essential for food safety, operational efficiency, and regulatory compliance. By following this systematic approach—preparing properly, applying effective cleaning solutions, removing water completely, and sanitizing thoroughly—you’ll maintain floors that support rather than hinder your operation’s success. Establish consistent cleaning schedules, document your activities, and address problems promptly to extend floor life and reduce long-term maintenance costs. Your freezer floor works hard in extreme conditions; give it the attention it deserves and it will serve your facility reliably for years to come.