Freezer Truck Repair: Quick Fix Guide

Your freezer truck’s temperature alarm just blared while you’re 200 miles from home. That sinking feeling hits as you realize thousands of dollars of perishable cargo is at risk. When your refrigeration unit fails mid-route, every minute counts toward preventing total cargo loss. Understanding where to find qualified freezer truck repair services across the United States isn’t just convenient—it’s essential for protecting your bottom line and maintaining your reputation with clients. This guide reveals exactly where to locate specialized repair shops, how to use mobile technology to find help fast, and proven strategies to minimize downtime when your reefer unit fails unexpectedly.

The reality is stark: without immediate intervention, a failed refrigeration unit can destroy an entire load of temperature-sensitive goods within hours. From frozen foods to pharmaceuticals to seafood, your cargo’s value evaporates quickly when the cold chain breaks. With approximately 4,000 specialized reefer repair businesses operating across the United States, knowing where these services are concentrated and how to access them efficiently separates successful operators from those facing costly breakdowns. Whether you manage a single owner-operator vehicle or a large refrigerated fleet, this guide provides the actionable intelligence you need to keep your freezer truck running reliably.

Where to Find Freezer Truck Repair Shops by State

Texas leads the nation with 270 dedicated freezer truck repair businesses, making it the most reliable state for finding immediate service along major distribution corridors. If you’re hauling refrigerated freight through the Lone Star State, you’ll have more repair options than anywhere else in the country—particularly valuable along I-10, I-20, and I-35 where cross-border and domestic freight traffic creates constant demand for reefer maintenance.

Why California and Florida Rank Second and Third for Repair Availability

California follows closely with 224 freezer truck repair establishments, concentrated around Los Angeles, Oakland, and San Diego ports where massive volumes of temperature-controlled imports and exports require constant maintenance. Florida’s 188 repair facilities serve the state’s extensive agricultural output and year-round perishable goods imports, with highest density around Miami, Tampa, and Jacksonville.

Michigan’s 208 repair shops support the Great Lakes region’s manufacturing and agricultural transportation needs, while Ohio (175 shops) and Virginia (173 shops) provide critical coverage along East Coast freight corridors. The Southeast shows particularly strong infrastructure with Kentucky (168), Illinois (166), and Georgia (157) offering substantial repair options for operators moving goods through this critical transportation region.

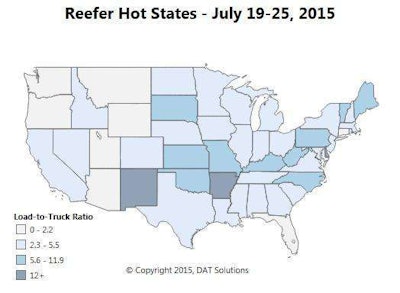

Top States with Most Freezer Truck Repair Emergencies

Oklahoma tops the list with 18,883 recorded freezer truck repair visits, revealing it as a critical state where refrigerated haulers frequently need emergency assistance. This high utilization rate makes establishing relationships with Oklahoma repair shops essential if your routes regularly cross through this key distribution corridor—particularly along I-40 and I-44 where refrigerated freight traffic is heaviest.

Why Maine and Alaska Have Surprisingly High Repair Rates

Maine’s 14,825 service visits seem disproportionate to its size but make perfect sense when you consider the state’s dependence on seafood exports. Any refrigeration failure here can devastate cargo value, driving operators to seek immediate repair service at the first warning sign. Similarly, Alaska’s 8,413 service engagements reflect the unique challenges of maintaining refrigeration units in extreme climate conditions where failures carry particularly high consequences.

Pennsylvania follows Oklahoma with 18,181 freezer truck repair visits, reflecting the intense freight movement through this northeastern distribution hub. California’s 17,239 visits align with its position as the nation’s largest freight gateway, while Minnesota’s 13,808 visits serve the agricultural product transportation that dominates the state’s freight economy.

How to Locate Freezer Truck Repair Services on the Road Using Mobile Apps

Modern mobile directory applications provide freezer truck operators with offline access to over 18,000 repair service locations across North America—critical when cellular coverage disappears in remote areas. These specialized trucking apps function without continuous internet connectivity, ensuring you can always find qualified reefer repair help even when traveling through dead zones where standard navigation apps fail.

3 Mobile App Features That Save Critical Time During Breakdowns

GPS-powered facility identification – The best apps automatically detect your location and display nearby freezer truck repair shops with real-time availability indicators, saving precious minutes when cargo temperatures are climbing.

Parts inventory verification – Advanced platforms show which facilities currently stock common reefer components like thermostats, condenser coils, and compressor parts, preventing wasted trips to shops that can’t fix your specific problem immediately.

One-tap emergency contact – Leading apps feature direct calling functionality with pre-populated service requests, allowing you to simultaneously navigate to a repair shop while explaining your emergency to a technician.

What to Do When Your Freezer Truck Breaks Down Mid-Route

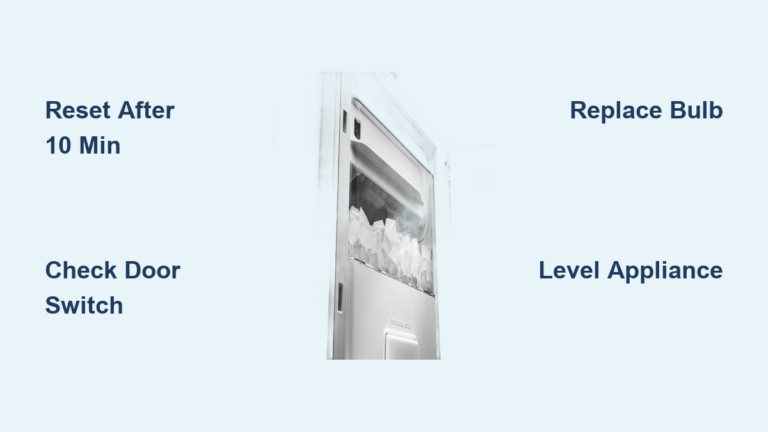

Immediately pull into the nearest safe location and perform a basic diagnostic check before calling for help—this simple step can cut your repair time by 30% or more. Most modern reefer units display error codes that pinpoint specific failures; writing down these codes before contacting a repair shop helps technicians prepare the right parts and tools for a faster fix.

Emergency Response Checklist for Failed Refrigeration Units

- Document current cargo temperature – Use a calibrated thermometer to verify actual cargo temperature versus what the unit displays

- Note any unusual sounds or smells – Compressor noises, burning odors, or excessive vibration provide critical diagnostic clues

- Check power connections – Loose electrical connections cause 22% of apparent “unit failures” according to industry data

- Verify fuel levels – Many reefer units share the truck’s fuel supply and will shut down when diesel drops below 1/4 tank

- Activate emergency temperature alerts – If your system has remote monitoring, trigger immediate notifications to your dispatcher

Pro Tip: Keep a thermal blanket in your cab to temporarily cover cargo during short delays—this simple measure can buy you 30-60 minutes of temperature stability while waiting for repair technicians.

Your Freezer Truck Preventive Maintenance Checklist

Schedule temperature calibration verification every 3 months or 15,000 miles—this often-overlooked task prevents gradual temperature drift that compromises cargo quality without triggering obvious warning signs. Even a 2-3 degree variance can accelerate spoilage of sensitive products like vaccines or premium seafood, yet many operators only discover calibration issues after cargo damage has already occurred.

4 Warning Signs That Mean Schedule Maintenance Now

- Extended compressor run times – If your unit runs continuously without reaching setpoint temperatures

- Excessive frost buildup – Ice formation beyond normal defrost cycles indicates airflow or refrigerant issues

- Inconsistent temperature readings – Variations between different cargo compartment zones

- Unusual operational noises – Grinding, clicking, or whining sounds from compressor or condenser

Critical Mistake to Avoid: Don’t wait for complete failure before addressing these symptoms—addressing developing issues early typically costs 60-70% less than emergency repairs after total breakdown.

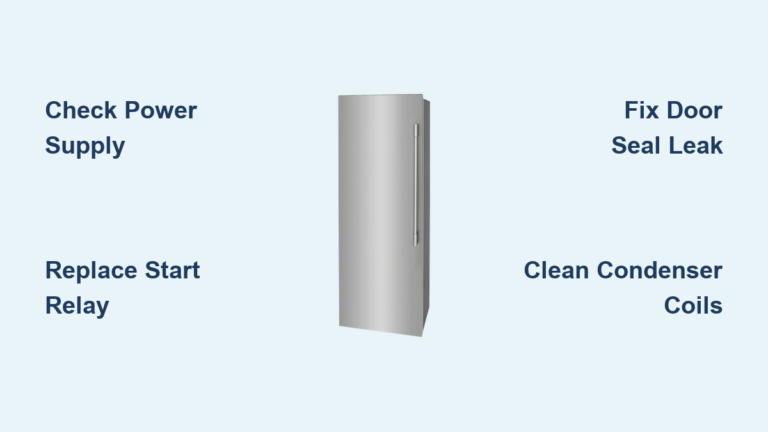

How Modern Diagnostics Are Changing Freezer Truck Repair Services

Today’s reefer units feature sophisticated microprocessors that store detailed operational data, transforming how technicians diagnose and repair failures. When you bring your freezer truck to a modern repair shop, technicians connect specialized scan tools that retrieve fault codes, operational history, and performance metrics—allowing them to pinpoint problems in minutes rather than hours.

Why Manufacturer-Specific Certifications Matter More Than Ever

Technicians without proper training on your specific reefer unit brand (Thermo King, Carrier, etc.) often misdiagnose electronic control issues, leading to unnecessary part replacements and extended downtime. Always verify that repair shops maintain current certifications for your particular equipment—this single factor can reduce your repair time by 50% or more when dealing with modern electronic systems.

7 Questions to Ask Before Choosing a Freezer Truck Repair Technician

“What’s your average response time for emergency reefer breakdowns?” A qualified shop should provide a specific timeframe (e.g., “within 2 hours for contract customers within 50 miles”) rather than vague assurances. This metric directly impacts your cargo loss exposure during emergencies.

Essential Questions for Repair Shop Vetting

- Do you stock common parts for my specific reefer unit model?

- Can you provide references from other refrigerated haulers?

- What’s your policy if the first repair attempt fails?

- Do you offer after-hours emergency service?

- How do you handle warranty claims for replacement parts?

- Can you perform repairs on location or must I bring the truck to your shop?

Establish relationships with at least three qualified freezer truck repair shops along your primary routes before emergencies occur—this network ensures you always have options when breakdowns strike in unfamiliar territory.

Freezer Truck Repair Strategies That Save Time and Money

Build strategic relationships with repair facilities in high-traffic corridors rather than relying solely on proximity—sometimes driving an extra 30 minutes to a preferred shop yields faster service than using the nearest location that’s fully booked. Fleet operators who maintain service agreements with multiple providers across their operational territory experience 40% less downtime during emergencies according to industry data.

Preventive maintenance represents your most cost-effective strategy—regular inspections and calibrations typically cost 20-30% of emergency repair expenses while preventing 75% of unexpected breakdowns. Schedule maintenance during natural downtime periods (like after delivering a load) rather than waiting for problems to develop, and always verify temperature calibration with an independent thermometer to catch subtle issues before they compromise cargo.

When selecting freezer truck repair services, prioritize shops with modern diagnostic capabilities and parts inventory over those offering the lowest prices—speed of repair directly impacts your cargo’s survival and your ability to maintain delivery schedules. By understanding where specialized repair resources are concentrated and establishing relationships before emergencies strike, you’ll transform freezer truck breakdowns from financial disasters into manageable service events.