Cyclopentane Freezer Leak: Causes and Fixes

Finding warm spots on your freezer’s exterior or noticing skyrocketing energy bills could signal a serious problem—cyclopentane leakage in your appliance’s insulation. This hydrocarbon blowing agent, used in polyurethane foam insulation since the 1990s, keeps your freezer running efficiently by maintaining thermal resistance. When cyclopentane escapes from the foam cells, your freezer’s cooling capacity plummets, forcing the compressor to work overtime. This comprehensive guide reveals how to identify cyclopentane leaks, implement immediate fixes, and prevent future insulation failures—saving you money on energy bills and protecting your frozen food investments.

Unlike refrigerant leaks that affect the cooling system directly, cyclopentane leaks compromise the insulation that keeps cold air contained. The good news is that with proper diagnosis and timely action, you can address this issue before it leads to complete appliance failure or costly food spoilage. Whether you’re noticing unusual frost patterns or your freezer runs constantly, understanding this specific problem gives you the power to make informed decisions about repair or replacement.

Why Your Freezer’s Insulation Is Failing

Cyclopentane (C5H10) serves as the environmentally friendly blowing agent that creates the closed-cell structure in polyurethane foam insulation. Replacing ozone-depleting CFCs and HCFCs, cyclopentane offers zero ozone depletion potential and a low global warming potential of just 11. During manufacturing, this hydrocarbon expands the foam mixture to create the thermal barrier that maintains your freezer’s internal temperature.

When cyclopentane escapes from the foam cells over time, the insulation’s R-value—the measurement of thermal resistance—decreases proportionally. This degradation forces your compressor to work significantly harder to maintain the set temperature of -18°C (0°F). The compound’s boiling point of 49°C (120°F) means it remains stable under normal freezer operating conditions, but physical damage or aging can create escape pathways. Understanding this process explains why your freezer suddenly struggles to maintain consistent temperatures despite appearing otherwise functional.

Spotting a Cyclopentane Leak Before Damage Worsens

You don’t need specialized equipment to identify potential cyclopentane leakage—these observable signs tell you when trouble is brewing:

Performance red flags appear first and include your freezer running continuously without reaching proper temperature, inconsistent cooling throughout the compartment (frozen items in one area while others soften), and unexplained spikes in energy consumption. Many homeowners report 20-50% increases in electricity bills as the compressor works overtime to compensate for compromised insulation.

Physical warning signs become visible as the problem progresses. Check for soft spots when pressing gently on exterior cabinet walls—this indicates degraded foam structure inside. Bulging or deformed panels, particularly on sides and back, signal advanced insulation failure. Unusual frost accumulation on the floor or ceiling (not just walls) and strange odors when opening the door provide additional confirmation of foam breakdown.

Pro Tip: Place your hand on different exterior surfaces—consistent cold is normal, but warm spots indicate where heat penetrates through compromised insulation. This simple test takes seconds but provides valuable diagnostic information.

Common Causes of Insulation Failure

Cyclopentane leaks typically develop from one of three primary sources, each requiring different solutions:

Manufacturing defects often surface in older units (10-15 years) where incomplete foam curing created weak spots. Improper mixing during production or inadequate sealing at joints provides pathways for gradual gas escape. Units from the late 1990s and early 2000s—during the transition to cyclopentane—are most susceptible to these inherent flaws.

Physical damage creates immediate escape routes through the foam structure. Dropping your freezer during moving, sharp impacts against cabinet walls, or even prolonged leaning during installation can crack the insulation. These problems might not show symptoms immediately but develop over months as cyclopentane gradually escapes.

Environmental factors accelerate natural aging of the polyurethane foam. Extreme temperature fluctuations in unheated garages, high humidity environments, and exposure to harsh cleaning chemicals all degrade the foam structure over time. Critical Warning: Never use abrasive cleaners on your freezer interior—they can damage the foam surface and seals, creating entry points for moisture that further compromises insulation.

Quick Diagnostic Tests You Can Perform Today

Before calling a technician, conduct these simple home assessments to confirm cyclopentane leakage:

-

Temperature mapping: Place multiple thermometers throughout your freezer and record readings after 24 hours. Significant variations (more than 2-3°C) between locations indicate insulation problems.

-

Energy consumption check: Compare current electricity usage with the same period from previous years. A 20%+ increase with no change in usage patterns strongly suggests insulation failure.

-

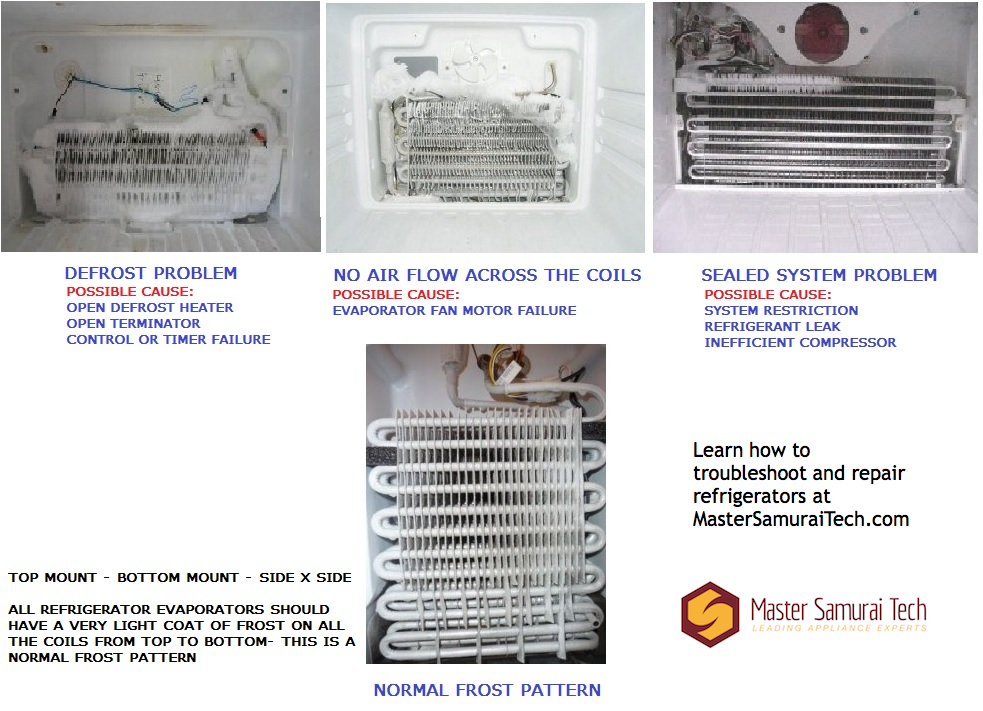

Frost pattern analysis: Normal frost appears evenly on evaporator coils and clears during defrost cycles. Abnormal frost accumulating in corners or on floor/ceiling points to air infiltration through compromised insulation.

-

Door seal test: Close a dollar bill in the door seal at various points—properly functioning gaskets should hold the bill firmly. Weak seals allow warm, humid air to enter, accelerating foam degradation.

Common Mistake: Don’t confuse cyclopentane leaks with refrigerant issues. If your freezer isn’t cooling at all, the problem likely involves the refrigeration system rather than insulation.

Immediate Actions to Limit Further Damage

When you suspect cyclopentane leakage, these steps protect your food and prevent the problem from worsening:

-

Reduce door openings: Every time you open the freezer, warm air enters and forces the compressor to work harder. Keep a list on the door of contents to minimize search time.

-

Group food items together: Concentrating frozen mass in the center creates thermal stability, as clustered items help maintain cold temperatures better than items spread along compromised walls.

-

Install an appliance thermometer: Monitor actual temperatures rather than relying on the dial setting. Consistent readings above -15°C indicate serious insulation problems.

-

Clean door seals: Use warm water and mild soap to remove debris that prevents proper closure. A tight seal reduces the workload on your struggling insulation.

Time-Sensitive Action: If temperatures rise above -12°C for more than 4 hours, transfer valuable items to temporary storage. Partially thawed foods refrozen without cooking may develop dangerous bacteria concentrations.

Evaluating Your Repair Options

Your solution path depends on the severity of the cyclopentane leak and your freezer’s age:

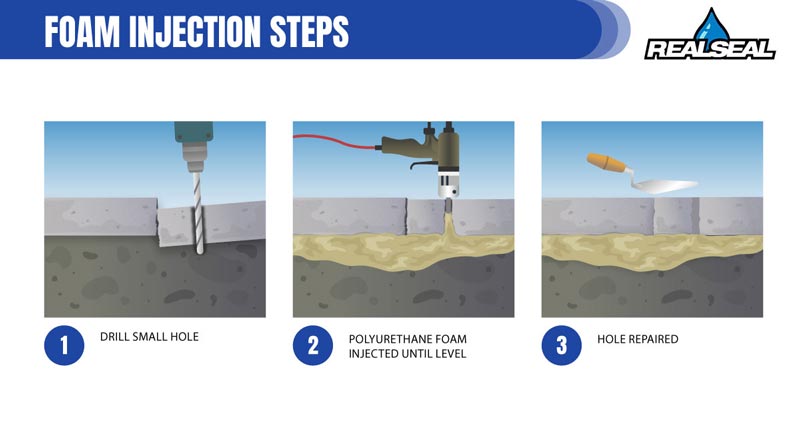

Foam injection repair works for localized damage where only specific areas have lost insulation integrity. Technicians inject expanding foam through small access holes to fill voids. This $200-$400 service provides temporary relief but rarely matches original insulation performance. Best for units less than 10 years old with isolated damage.

Partial cabinet replacement becomes necessary when one panel (side, back, or top) shows extensive degradation. This $500-$800 repair replaces the damaged section with new insulated material. Availability of replacement parts depends on your model’s age—manufacturers typically support parts for 7-10 years after production ends.

Complete replacement makes financial sense when repair costs exceed 50% of a comparable new unit’s price. Modern ENERGY STAR models use 10-15% less energy than decade-old units, potentially offsetting the purchase price through utility savings within 3-5 years.

Expert Recommendation: For units older than 12 years with widespread insulation failure, replacement is almost always more cost-effective than repair. The underlying foam structure has likely degraded throughout, making any repair temporary.

Preventing Future Insulation Failures

Extend your next freezer’s lifespan with these proven prevention strategies:

-

Ensure proper ventilation: Maintain at least 3 inches of clearance around condenser coils to prevent overheating that stresses insulation materials.

-

Control ambient conditions: Avoid placing freezers in unheated garages (where winter temperatures drop below freezing) or near heat sources like ovens.

-

Practice proper loading: Allow hot foods to cool to room temperature before freezing, and avoid blocking internal air vents with large items.

-

Maintain consistent humidity: In damp environments like basements, use a dehumidifier to reduce moisture that accelerates foam degradation over time.

Monthly Maintenance Checklist:

– Inspect door seals for cracks and debris

– Clean seals with baking soda solution

– Verify interior temperature with appliance thermometer

– Check for consistent cold on exterior surfaces

A cyclopentane leak doesn’t have to end your freezer’s service life prematurely. By recognizing early warning signs, implementing immediate damage control measures, and choosing the right repair path, you can restore efficient operation and protect your food investments. For units approaching 10-15 years of age—the typical service life of polyurethane foam insulation—regular professional assessments become increasingly important. Remember that while cyclopentane leaks develop gradually, taking prompt action when you notice performance changes can save hundreds in energy costs and prevent costly food spoilage. When repair becomes impractical, modern freezer technology offers significant efficiency improvements that justify replacement while reducing your environmental footprint.